Summary for Decision-Makers

Manufacturing is moving beyond automation toward AI-driven ambient intelligence — where machines can think, learn, and adapt in real time.

Titan Technology helps factories transform into self-optimizing ecosystems that predict issues, reduce downtime, and improve efficiency.

Our step-by-step approach ensures safe, practical adoption — from infrastructure readiness and smart data pipelines to AI deployment and continuous learning.

Real-world results include up to 35% improvement in product quality, 20% higher production capacity, and 15% fewer equipment failures.

Designed for scalability and sustainability, Titan’s AI solutions empower manufacturers to work smarter, not harder, and stay competitive in the new era of intelligent manufacturing.

At Titan Technology, we believe the future of manufacturing is no longer a distant vision—it's happening now. Thanks to AI-driven ambient intelligence, factories today are transforming into more intelligent, more adaptive environments that think and respond like never before. Instead of relying on traditional automation that simply follows fixed rules, we are moving toward intelligent systems that can predict issues before they arise, adjust operations in real-time, and optimize production without human intervention.

As a trusted technology partner with deep expertise in AI solutions, we aim to bring this cutting-edge capability to manufacturers ready to take the next leap toward efficiency and innovation. From predictive maintenance that prevents costly downtime to AI-powered quality control that eliminates defects before products leave the line, we help businesses create seamless, intelligent factory environments that work smarter, not harder.

The real question is no longer whether businesses will adopt this technology, but how soon they will embrace it to stay competitive. (Discover how leading manufacturers leverage AI for a competitive edge in this Forbes article: How AI Is Changing the Game in Manufacturing – Forbes). At Titan, we are here to guide companies through that journey, making AI-driven ambient intelligence a practical, accessible solution for modern manufacturing—even for those who are not IT experts.

How We Apply Ambient Intelligence in Manufacturing

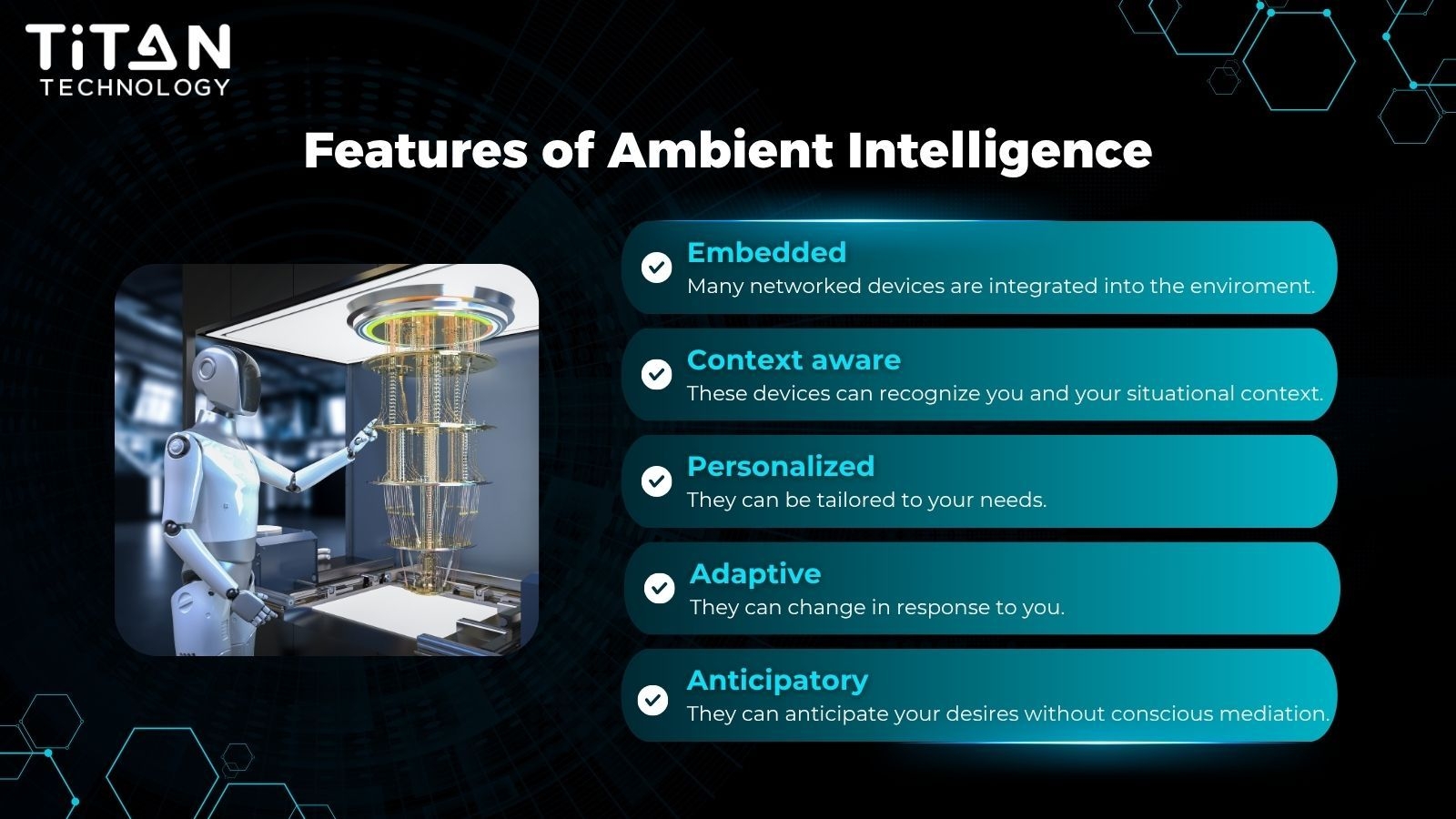

We see ambient intelligence as more than just a buzzword — it's a practical way to help factories become more innovative, faster, and more efficient. So, what does ambient intelligence mean for manufacturers? Simply put, it’s about creating intelligent factory environments where machines, sensors, and AI systems work together automatically to make decisions and solve problems without waiting for humans to step in.

Unlike traditional automation that follows fixed instructions, ambient intelligence allows factory systems to learn and adapt continuously. These AI-powered environments can sense what's happening on the factory floor, analyze that information in real-time, and act—all while improving themselves over time.

Let us show you how this works through real-life examples from manufacturing operations that we help transform:

AI that Sees and Understands

With the help of advanced sensors and AI, machines can now "see" their surroundings, much like how we rely on our eyes to understand the world. Using computer vision, smart sensors, and AI models, factory equipment can detect minor defects that humans might miss—like a scratch on a car door or a misaligned part on an assembly line.

Imagine a factory producing thousands of parts a day. Instead of waiting until a faulty product is discovered at the end of production, AI can spot defects quickly and alert the system—saving time, materials, and costs. At Titan, we help companies set up these AI-driven perception systems to maintain the highest quality without slowing down production.

AI that Makes Smart Decisions

But ambient intelligence goes beyond just spotting problems. The real value comes when AI systems can make decisions automatically. For example, if a machine detects that a shipment of materials is delayed, AI can reorganize production schedules on its own—so the factory doesn’t lose precious time. Instead of waiting for human managers to fix every issue, AI keeps the entire operation running smoothly.

At Titan Technology, we design AI systems that are trained to understand real manufacturing challenges—from handling supply chain disruptions to adjusting workflows based on equipment performance—helping factories avoid costly delays and keep output on track.

AI that Acts Autonomously

Taking it a step further, ambient intelligence includes Physical AI, which allows machines to act without human input. Imagine robotic arms in an automotive factory that don’t just assemble parts but also adjust their movements in real-time based on what they "see" and "feel" from sensors. If a robot detects its motor overheating, AI can pause its operation, notify maintenance teams, and shift work to other machines to avoid downtime.

Titan helps factories bring this level of intelligence to life by integrating AI-powered systems that monitor, decide, and act — making factories more resilient and productive.

Why This Matters: Smarter, More Efficient Factories

By bringing together these layers—AI that perceives, decides, and acts—ambient intelligence eliminates waste, reduces human error, and boosts production efficiency. More importantly, it empowers factory workers to focus on higher-value tasks while AI handles routine monitoring and problem-solving in the background.

At Titan Technology, we don’t believe AI should replace people. Instead, we design AI systems that work alongside teams, enhancing their capabilities and ensuring that factories can adapt to change quickly, without disruption.

Titan’s Step-by-Step AI for Smarter Manufacturing

At Titan Technology, we understand that adopting AI-driven ambient intelligence can sound like a complex transformation, especially for manufacturing companies that are focused on daily operations. That’s why we approach this process step by step, making it practical, measurable, and tailored to each business. We aim to help manufacturers move smoothly from traditional production to intelligent, self-optimizing factories—without disrupting ongoing work.

Here’s how we guide our clients on this journey:

Step 1: Preparing Your Factory for AI

Before AI can help make real-time decisions or improve production, we must ensure that your factory has the proper foundation to support intelligent systems. This means focusing on three essential areas:

Strong Infrastructure: AI needs robust systems to process data quickly and accurately. That could include on-site edge computing or cloud-based solutions to analyze information from machines and sensors in real time. If the infrastructure is too slow, AI won’t be able to react in time to prevent issues, like detecting a faulty part before it moves down the production line. At Titan, we assess your current technology and recommend scalable, cost-effective solutions that match your needs.

High-Quality Data: AI learns from data—the better the data, the smarter the AI becomes. We help factories gather, clean, and organize the right kind of data from existing machines, sensors, and operations. For example, AI needs consistent, detailed images and sensor readings to detect defects in car doors. Without clean data, AI might miss problems or create false alarms. Our team works closely with manufacturers to build strong data pipelines that AI can trust.

Reliable Connectivity: All factory parts must communicate seamlessly for AI to act in real time. Whether it’s 5G networks, IoT (Internet of Things) devices, or machine-to-machine communication, we ensure fast, stable connections that allow AI to monitor and control factory systems without delays. This keeps everything synchronized, from production lines to warehouse logistics.

Step 2: Training and Deploying AI Systems

Once the foundation is established, Titan helps companies train AI models to understand their unique factory environment. Unlike basic automation, AI must learn from actual factory data and situations to make accurate decisions. Here’s how we do that:

Integrating Smart Sensors: First, we implement advanced sensors that provide AI with a detailed view of factory operations. These sensors measure things like temperature, pressure, movement, and alignment, helping AI create a "real-world map" of how your factory works. At Titan, we help factories choose the right types of sensors and integrate them smoothly into existing systems.

Using Digital Twins for Virtual Training: Before AI operates on the actual production floor, we recommend testing it in a virtual environment called a Digital Twin. This is a digital copy of your factory where AI can practice making decisions and adjusting workflows without risking actual production. For example, if you’re launching a new product model, AI can simulate the assembly process in the Digital Twin to optimize the movements of robotic arms and conveyor belts, avoiding mistakes when production begins. Titan develops customized Digital Twins so AI can learn safely and efficiently.

Supporting Human Workers: At Titan, we always emphasize that AI’s role is to support, not replace, people. AI can handle repetitive monitoring tasks, but humans bring critical thinking and experience that AI still can’t replicate. That’s why our AI systems are designed to alert workers to issues, offer suggestions, and share insights while leaving the final decisions to human experts. For instance, if AI notices a machine’s torque is off, it will notify technicians for inspection, empowering teams to make informed choices faster.

Step 3: Continuous Learning and Optimization

Manufacturing environments are dynamic—new products, changing suppliers, and shifting demands mean that AI must constantly evolve. At Titan Technology, we help companies set up AI systems that keep learning and improving every day by:

Analyzing Real-Time Data for Adjustments: AI analyzes data from machines and processes to fine-tune operations in real-time. For example, if sensors show that a welding machine is running hotter than usual, AI can suggest slowing down the line to prevent damage and maintain quality.

Learning from Past Performance: AI reviews historical data to spot patterns and improve future performance. Suppose AI notices that a specific component often causes delays during assembly. It can recommend changes in workflow or alternative materials, helping factories stay proactive rather than reactive.

Collaborating with Human Operators: AI doesn’t operate in isolation. Our approach combines AI insights with human knowledge. Workers can give feedback when AI makes a recommendation—like adjusting a production schedule—and AI learns from that input to make better suggestions next time. This creates a continuous improvement loop where both AI and people get smarter together.

The Real Value of AI-Driven Ambient Intelligence for Business

At Titan Technology, we focus on practical outcomes — not just theories or future promises. By applying AI-driven ambient intelligence, we help manufacturers see accurate business results that translate directly into better performance, lower costs, and higher customer satisfaction.

So, what can companies realistically expect when adopting AI-powered solutions in their factories? Let’s explore three core areas where businesses partnering with Titan have already seen measurable improvements.

1. Self-Optimizing Production Lines: Smarter, Faster, and More Cost-Effective Operations

Imagine a production line that doesn’t wait for managers to notice problems or adjust workflows. With ambient intelligence, AI monitors the entire production process in real-time, adjusting automatically to keep everything running at peak performance.

For example, if AI detects a machine running slower than expected, it can rebalance workloads between other machines to avoid bottlenecks. If energy costs spike at a particular time of day, AI can suggest shifting production to off-peak hours, saving money without reducing output.

At Titan, we help manufacturers deploy AI systems that continuously analyze production data and make intelligent decisions to keep operations running smoothly — reducing downtime and cutting unnecessary costs.

Results You Can Expect:

Higher production output with existing resources.

Reduced energy usage and lower operational costs.

Faster response to unexpected production issues — without human delays.

2. Proactive Forecasting: Staying Ahead of Supply Chain and Production Challenges

One of the biggest risks in manufacturing is disruption — whether it’s a supply chain delay, a sudden surge in demand, or a quality issue that holds up production. With AI-driven ambient intelligence, factories don’t have to wait for these problems to happen. AI analyzes vast amounts of data to forecast issues before they impact production.

For example, AI can predict when a key supplier may face delays or when raw materials will run low. Based on these insights, AI recommends adjusting production schedules or finding alternative suppliers — avoiding downtime, and keeping customer deliveries on track.

Titan helps businesses set up AI forecasting models that connect to supply chains, inventory systems, and production planning tools so leaders have the information they need to make smarter decisions — before minor issues become big problems.

Results You Can Expect:

More accurate production and demand forecasts.

Fewer last-minute delays and emergency fixes.

Better inventory and supply chain management — reducing waste and cost.

3. Autonomous Quality Control: Improving Product Quality and Reducing Waste

Quality control is critical in manufacturing — but manual inspections take time, cost money, and are prone to human error. With AI-driven quality monitoring, factories can automatically detect defects in real time, stopping faulty products before they reach customers.

At Titan, we help implement AI-powered vision systems and smart sensors that inspect products as they are being made, spotting defects like misaligned parts, scratches, or structural weaknesses. And because AI learns from every inspection, it gets better and more accurate over time, ensuring higher consistency in production.

For manufacturers, this means better products, fewer returns, and less waste — directly improving profitability and customer satisfaction.

Results You Can Expect:

Fewer defective products are reaching customers.

Less material waste and lower rework costs.

Stronger customer trust due to consistent quality.

Real-World Value: Measurable Gains from AI Adoption

The impact of AI-driven ambient intelligence isn’t just theoretical — companies worldwide are already seeing measurable gains, and Titan Technology is ready to help manufacturers in Vietnam and globally achieve the same.

Up to 15% increase in production uptime thanks to AI predictive maintenance — reducing unplanned equipment breakdowns.

Up to 35% improvement in product quality through AI defect detection — minimizing costly errors.

Up to 20% boost in overall production capacity with AI-optimized workflows — delivering more output without new investments.

These numbers show that AI isn’t just about future potential — it’s a practical tool for improving today’s factory performance.

Why Work with Titan Technology?

At Titan Technology, we don’t just install AI tools — we partner with manufacturers to design intelligent solutions that fit their unique business needs. Whether you’re starting with one production line or looking to transform your entire factory, our experts are here to guide you through every step, from planning and setup to continuous improvement.

Our deep experience in AI, automation, data engineering, and software development makes us a trusted partner for businesses ready to adopt intelligent manufacturing. And because we understand that every factory is different, we deliver flexible, scalable solutions built for real-world challenges — not generic off-the-shelf software.